L7 | CHATS

product highlight

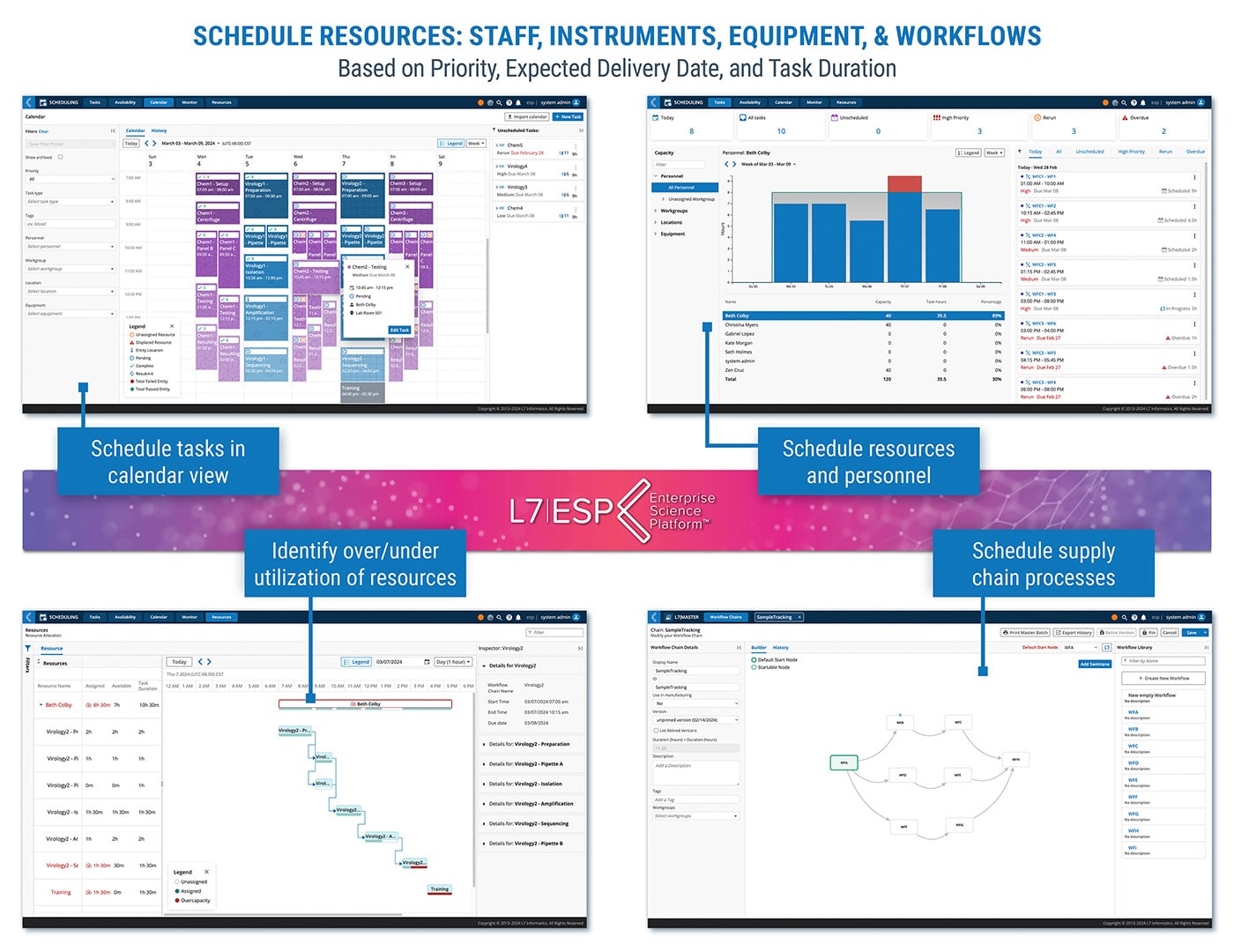

L7 Scheduling – A Comprehensive Scheduling Solution to Maximize Product Capacity & Meet Operational Efficiency

by Brigitte Ganter | posted on March 12, 2024

Manufacturing of pharmaceutical products and managing/monitoring patient treatment are highly regulated and complex processes. This is the more challenging as efficiency and cost factors come into play. The complex supply chain for cell and gene therapy (CGT) production and patient treatment management/oversight must be fast for the treatment to work. In addition, manufacturing processes of biologics (e.g., monoclonal antibodies) must also run at the lowest possible cost. As such, achieving maximum production capacity and improving operational agility is of the highest importance for any therapeutics manufacturing facility or laboratory. Efficient and cost-effective production of high-quality therapies requires overcoming one of the biggest hurdles the industry is facing, namely suboptimal production and planning schedules resulting in operational inefficiencies. An optimized production and planning schedule represents a key requirement to guarantee faster and lower-cost delivery of high-quality therapeutic products and entails optimizing the laboratory (and manufacturing) resources at hand, be it qualified staff, instruments, or equipment. Furthermore, adhering to regulatory standards and full compliance is an absolute must, and this without sacrificing operational efficiency.

The L7|ESP Scheduling Application Offers the Solution to Overcome Production and Patient Treatment Challenges Pharmaceutical Manufacturing Departments and Organizations Face

The L7|ESP Scheduling application is not a standalone offering, but rather is fully integrated into the flexible, secure, and collaborative digital and process-oriented L7|ESP platform designed to overcome traditional pharmaceutical manufacturing bottlenecks.

The L7|ESP Scheduling application:

- Dynamically and automatically links entries to L7|ESP schedulable data sources.

- Enables resource scheduling based on priority, expected completion date, and task duration.

- Integrates assignee information with workgroup, location, and selected equipment into the scheduling process.

- Automatically synchronizes with MES and LIMS applications.

- Is part of the L7|ESP Unified Platform, seamlessly contextualizing data and orchestrating workflows throughout its analytical and manufacturing ecosystem.

- Supports real-world process supply chain complexities and their scheduling.

- Ensures 21 CFR Part 11 compliance for production of small molecules, biologics, and CGT products.

The L7|ESP Scheduling Application Outperforms Traditional, Standalone Scheduling Solutions

Recent advancements in digital technologies, like the L7|ESP Scheduling application, have started to shape the entire life sciences and healthcare value chains by streamlining and optimizing lab and business processes. The L7|ESP Scheduling application is part of the L7|ESP Unified Platform, with its Workflow Orchestration and Data Contextualization System, where manufacturing execution system (MES) data resides in the same database as LIMS, inventory data, and a myriad of other applications. The system uses existing L7|ESP workflow chain configurations to automate task orchestration and, therefore, provides a holistic approach to lab process management. L7|ESP can be extended with data trending and charting tools for single-batch and cross-batch trending and reporting.

Specifically, with the L7|ESP Scheduling application you can now:

- Run laboratories and manufacturing plants at capacity 24/7/365.

- Assess and plan resource capacity and adjust schedules accordingly.

- Monitor task progress in real-time.

- Optimize resource utilization with automatic combinations of instrument/equipment run times, staff schedules, and planned workflows.

- Optimize instrument/equipment usage and longevity, minimize downtime, and preemptively plan new instrument investments.

The L7|ESP Scheduling Application is for Laboratory and Project Managers

L7|ESP Scheduling optimizes laboratory and business processes across therapeutics, drug manufacturing, and diagnostic testing.

- Laboratory and Project Managers across therapeutics, drug manufacturing, and diagnostic testing, including process development & analytical development.

- Research, Therapeutics, and Diagnostic Laboratory Managers who need to optimize their resources and their staff to be more efficient and cost-effective and want their staff to focus on science instead of low value activities.

By utilizing the Scheduling application as part of the L7|ESP Unified Platform allows researchers to run their laboratories at capacity with optimized resource utilization and staff schedules. Automating the administrative burden with L7|ESP allows laboratory staff to focus on high value activities while optimizing production cost-effectiveness.