L7 | CHATS

product update

L7 Scheduling Builds on Embedded Workflows to Maximize Production Capacity and Operational Efficiency

by Isaac Rodriguez | posted on August 07, 2024

Non-optimized production and planning schedules of highly regulated and complex processes are often still the norm across many laboratories and therapeutic manufacturing sites today. Examples of such complex processes include supply chain bioprocesses for cell and gene therapy (CGT) production and patient treatment management/oversight, clinical research activities, diagnostic test development and optimization, and clinical trial management. Common to all these scenarios is that time is of the essence, and any loss of efficiency negatively affects business return on investment (ROI) due to higher production costs and subsequent reduced revenues.

Consider now for a moment a fully integrated, highly flexible, secure, and collaborative scheduling solution designed to overcome your traditional research, diagnostics test development, and therapeutics manufacturing bottlenecks!

I am excited to share with you the details of the newly developed L7 Scheduling application, which is fully embedded in the Unified Platform L7|ESP® with its Workflow Orchestration and Data Contextualization – a solution that is critically helpful to laboratories and therapeutic manufacturing units. And do not just think of scheduling personnel resources; no, you can also schedule workgroups, locations, equipment, and custom resources. L7 Scheduling manages the schedules of all these resources and dynamically and automatically links to entries and schedulable data sources.

L7 Scheduling allows defining resource schedules, planning and reviewing resource capacity, scheduling tasks and assigning resources, reviewing task progress in real-time, and monitoring resource utilization across tasks. Since L7 Scheduling is fully integrated within the L7|ESP Unified Platform with its Workflow Orchestration system, resources are dynamically and automatically linked to entries and schedulable data sources. L7 Scheduling enables optimized resource allocation, which results in diagnostics and therapies that benefit the entire organization, providing metrics that are most relevant to laboratory and manufacturing directors and C-level individuals (e.g., CFO, CEO, COO, CSO, CMO, CTO).

L7 Scheduling highlights include:

- Resource scheduling based on priority, expected completion date, and task duration.

- Optimizes resource utilization with automatic combinations of instrument and equipment run times, staff schedules, and planned workflows.

- Optimizes instrument/equipment usage and longevity, minimizes downtime, and preemptively plans new instrument investments.

- Schedules Tasks and assigns resources.

- Schedules Entities that are marked as “Schedulable.”

- Assesses and plans resource capacity and adjusts schedules accordingly.

- Integrates assignee information with workgroup, location, and selected equipment into the scheduling process.

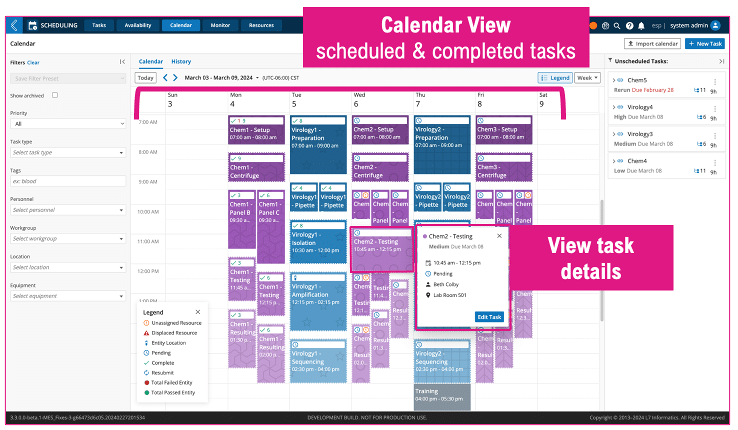

- Provides an intuitive Calendar View with all necessary details to view all tasks, whether scheduled or already completed, pending (i.e., scheduled in the future), and Tasks currently undergoing Entity processing via L7 LIMS. Completed Tasks show the total number of passed versus failed Entities.

- Synchronizes automatically with L7 LIMS.

- Supports real-world process supply chain complexities and their scheduling.

- Monitors Task progress in real-time.

- Ensures that laboratories and manufacturing plants run at capacity 24/7/365.

- Supports the creation and maintenance of manual and auto-generated Tasks.

- Schedules Workflows (WFs) and Workflow Chains (WFCs) and associates Tasks with a WFC.

L7 Scheduling is a must-have for all laboratory directors, manufacturing site heads, and projects/program managers.

Assess, Plan, Maintain, and Update Resource Availability

The end-users who benefit the most from L7 Scheduling are the lab directors, manufacturing site heads, and program/project managers, but of course, also the lab technicians and bench researchers who must execute experiments and keep track of the progress. Basically, anyone who must assign and manage schedules and experiments, or anyone who must follow a strict laboratory and manufacturing processing throughput plan.

For the lab director, manufacturing site head, and program/project manager: L7 Scheduling allows these individuals to view the availability of different resources (e.g., an individual team member or a specific piece of equipment) on a daily, weekly, and monthly basis, define a new schedule for a given resource, view and manage existing schedule details, or discontinue/disable the availability of a resource. Furthermore, the manager can also assign resources to all tasks and modify resource assignments as a schedule is planned. This helps with reducing and resolving scheduling conflicts across the entire process. An intuitive, one view user interface, the Calendar View, provides the capability to see resource availability and to request, schedule, monitor, and discontinue resources. Specific tasks of individual team members (e.g., bench researchers or lab technicians) are assigned in the Task Bucket in the Task Review Panel (see Figure 1).

For the lab technician and bench researcher: L7 Scheduling allows those executing a specific process to see on a daily, weekly, and monthly basis what tasks need to be performed, what the expected task start and end dates are, and what equipment and instruments they will need to use to conduct the work (i.e., are associated with a specific task).

Plan and Review Resource Capacity

Optimal resource utilization requires understanding the over- and under-capacity of the various resources at hand. As shown in Figure 1, L7 Scheduling provides an intuitive and easy way to view assigned/unassigned resources and over- and under-capacity of any given resource (e.g., personnel). Resource capacity can be viewed on a daily, weekly, or even monthly basis. This allows managers to knowledgeably assign resources to specific tasks based on availability, capacity, and task durations.

Figure 1: Over- and undercapacity and task hours for a given staff member are color-coded, with blue being at capacity or undercapacity and red being overcapacity.

Schedule Tasks and Assign Resources

Viewing scheduled, pending, and completed tasks is important for both lab members (e.g., lab technician and bench researcher) and the manager (e.g., lab director, manufacturing site head, program/project manager) overseeing all activities and their progress. As shown in Figure 2, the Calendar View provides all necessary details to view all Tasks, whether scheduled or already completed, pending (scheduled in the future), or currently undergoing entity processing via L7 LIMS. Completed tasks show the total number of passed versus failed entities, workgroup, and equipment), and time and date. Tasks can be edited right from within the Task’s details view within the Calendar.

Tasks and Schedules can also be archived and filtered in the Calendar view, which helps reduce Calendar clutter and quickly find relevant Tasks. The Calendar view also shows Unscheduled Tasks in the right-hand panel (Figure 2) and supports dragging unscheduled Tasks into the Calendar by the manager. The Calendar view also allows scheduling resources and color/texture coding them to differentiate the newly added Tasks from other existing Tasks.

Figure 2: Calendar View of scheduled and completed tasks.

Monitor Task Progress

Another way to Monitor Tasks and their progress is via a list accompanied by a Gantt chart (not shown), which shows Tasks progress in real time. This is of particular interest to anybody who needs to monitor the progress of a Task, e.g., the lab director or program/project manager. Selecting a specific Task opens the Inspector panel providing Task information such as WFC Name, Start and End Time, Due Date, Experiment Description, assigned Personnel and Equipment, and more. Lastly, a Task manager can review the Baseline for Task Monitoring to compare the start and end times of a scheduled Task versus a completed Task and filter Tasks to focus on the Tasks of interest. The Baseline can be used to extrapolate data when comparing the real Task progression in L7 LIMS versus the projected Task as scheduled in the Calendar.

Schedule Entities Marked as “Schedulable”

L7|ESP offers four out-of-the-box resource types that can be scheduled in addition to custom resource types. Out-of-the-box resource types include personnel, workgroups, equipment, and locations.

Custom resource types, which can be added in L7|MASTER® by creating an Entity Class, can also be scheduled, simply by turning the “Schedulability” flag on. Entity Types that are created from Entity Classes with the “Schedulability” flag on are schedulable in L7 Scheduling. Therefore, Entities marked as “Schedulable” can then be scheduled based on priority, expected completion date, task duration, and assignee information. This is particularly useful for lab managers/directors assigning entities to be processed by the lab personnel.

Create and Maintain Manual and Auto-Generated Tasks

Also controlled within the L7 Scheduling application are manual and auto-generated Tasks. This includes:

- Auto-generated Tasks created from WFs and WFCs and that have been submitted as “Schedulable” Tasks.

- Events, meetings, and out-of-office days that affect an individual’s schedule and capacity can be monitored via the L7 Scheduling application as Tasks.

- Starting a worksheet in L7 LIMS and having the associated unscheduled Task auto-scheduled based on the start and end time.

Scheduling WFs and WFCs and Associate Tasks to a WFC

L7 Scheduling also supports scheduling WFs and WFCs, including non-linear WFCs. Additional scheduling actions associated with WFs and WFCs include scheduling/submitting WFs and WFCs, including non-linear WFCs, which will be displayed on the Calendar View and can be reviewed in the Monitor section; selecting a start node and have only downstream nodes that can accept samples displayed in the scheduling Calendar; filtering WFs and WFCs by resource type; scheduling a planned action within a WFC that is already in progress to account for major delays; selecting a WF or WFC on the Calendar view to display all WF details; scheduling non-linear WFCs which will return an approximation of when the WFC will be complete; editing and updating the scheduled date, assigned priority, and assigned due date of any WF and WFC; and scheduling Tasks, assign Tasks to a WF, and define WFC Task pattern to visually distinguish WFs within the same WFC.

L7 Scheduling is certainly a solution that you may want to look into.

Connect with us to learn more about L7 Scheduling and the L7|ESP platform, with its Workflow Orchestration and Data Contextualization, and how these could help you with your laboratory and business processes.