Business process management (BPM) focuses on improving corporate performance by managing and optimizing a company’s business processes to achieve business goals. BPM enables organizations to be more efficient, more effective, and more capable of customer-driven change.

By translating the core principles of BPM to scientific laboratory operations, L7 Informatics is creating a new category of enterprise software: Scientific Process & Data Management (SPDM). Think of SPDM as taking all your scientific processes to the next level of organization by having all the machine and human components blended together into one seamless workflow. L7’s Enterprise Science Platform (ESP) software is the first platform to fully enable SPDM by providing full transparency into your operations through streamlined sample tracking, data acquisition, and process coordination.

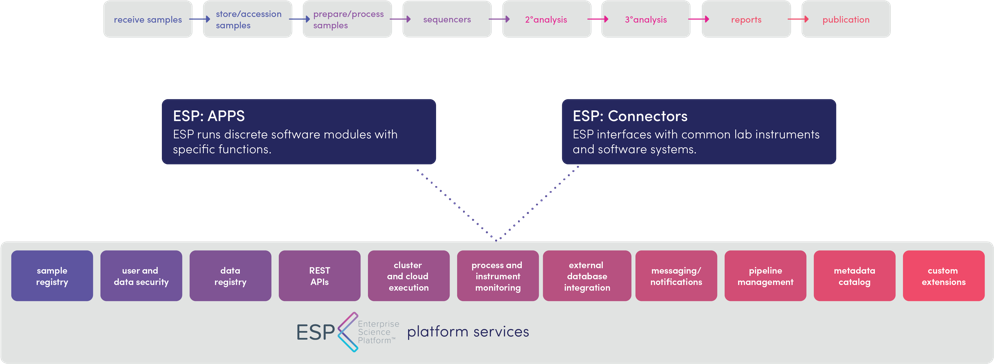

An overview of the streamlined workflow using SPDM principles available with L7 ESP.

Translating BPM Benefits to SPDM Benefits

The real question in assessing how BPM principles can be applied is: how does this benefit my lab’s operation? Here we present a brief overview of the science twist on some of the key benefits of BPM:

- Agility—Rigorous SPDM enables organizations to make changes to processes with minimal costs, while still maintaining the flexibility to customize solutions to the requirements of the organization.

- Productivity—Laboratories that process large numbers of samples in a production environment employ many routine workflows with repetitive protocols and analyses that SPDM can automate, freeing up technicians’ and bioinformaticians’ time to focus on processing more samples.

- Efficiency & Reduced Risks—Integrating all laboratory processes through SPDM enables the organization’s management to easily identify areas of inefficiency.

- Compliance & Transparency—SPDM ensures that laboratory organizations can implement regulatory requirements quickly, and labs using ESP as the backbone of their SPDM are assured of deep data provenance on all aspects of their workflows.

- Employee Satisfaction—The removal of traditional interfunctional silos relieves significant operational stress that is felt not only by the process itself, but also by the operators involved.

- Consistency, Repeatability, Transferability & Sustainability—With SPDM, each step of a laboratory workflow is carefully planned and documented, then executed as designed. Problems arising in these workflows are all addressed the same way, regardless of the operator.

- Measurability—With the full operational process in a laboratory maintained through SPM, organizations gain full insight into all aspects of their workflows. All processes can be measured and quantitatively analyzed for efficiency, productivity, and profitability.

- Technology Integration—With the whole lab running in concert, the traditional communication silos (e.g. wet lab vs. bioinformatics), are broken down, all laboratory platforms can be monitored, and inefficiencies can be more easily pinpointed and remedied.